1. Introduction

Thank you for using Hazcalc!

Hazcalc is a platform for assessing hazardous areas for flammable gases and liquids in relation to explosion safety. We started developing Hazcalc during our work as an Atex consulting company for hazardous areas.

During that time we often assessed existing workplaces and new installations, such as container skids and process installations, on hazardous areas. Among the methods that you can use for that, we

often used the methods as described in the IEC standards; for gas atmospheres the IEC 60079-10-1.

During the use of that standard, we developed an Excel worksheet, so that assessments could be performed in an easy way. We kept on developing and finetuning that worksheet, as we came to the point that we realised ourselves: why not sharing that useful tool with others?

We decided to develop a web-based platform where user can assess potentially hazardous areas in an easy and controlled way.

1.1 Competence of users

The tool should preferably be used by sufficient competent persons, e.g. persons who have knowledge on assessing hazardous areas and have knowledge of the IEC 60079-10-1 standards. Its preferable, but not mandatory, to execute assessment by sufficiently competent persons or let sufficiently competent persons control executed assessments. Users are always self-responsible for the content and accuracy of their assessments.

1.2 Possibilities

What kind of assessments can be done with this tool? We implemented various calculation methods in it. First of all, most of the relevant calculations that are within the IEC 60079-10-1 standard (version 2015 and 2020), such as:

Calculation of release rates:

- Calculation of the releases rate of liquids;

- Calculation of the release rate of gases or vapours;

- Calculation of the release rate of evaporative pools.

Beside that we added some useful features to the tool:

- Calculation of the release rate of filling containers or tanks with liquids;

- Manually insert of calculated release rates with other methods.

For all forms of release, the hazardous areas can be assessed by:

Evaluation of the dilution of released substances:

- Calculation of the average air velocity within a room;

- Override the calculated ventilation velocity for dilution manually;

- Insert the ventilation velocity for outdoor situations;

- Calculation of the background concentration for indoor situations;

- Automated classification of the dilution class;

- Automated plotting of the dilution class within a graph.

Classification of hazardous area:

- Automated classification of hazardous area’s based on inserted values;

- Automated calculation of the size of hazardous area’s;

- Automated calculation of the size of hazardous areas by extrapolation;

- Automated plotting of the size of hazardous areas within a graph.

Storage and Report

All assessments are stored in a personal or business account (with one or multiple users). The assessments with all relevant parameters can be printed or stored in an Acrobat PDF report and all raw data can be exported to your local machine in MS Excel format.

1.2.1 Main benefits of Hazcalc

The main benefits of using Hazcalc are:

- time saving due to e.g. integrated substance database, automated calculations, filtering, sorting assessments, copy functions and reporting function (single and batch reporting);

- less faults compared to manual calculations with e.g. Excel;

- professional apearance for cliënts, e.g. picture and company logo print on

report; - fully compliant to IEC 60079-10-1, both 2015 and the 2020 version.

1.3 Engineering purposes

The tool can useful for engineering purposes. Assessment can be made to evaluate the area dimensions and ventilation requirements in relation to the hazardous area to be applied. The pre-conditions to achieve a less hazardous area can be determined and calculations can be made to calculate the maximum concentration of substances within ducting.

2. Accounts

2.1 Creating an account

The use of the tool is only possible by creating an account so that one can login within the platform.

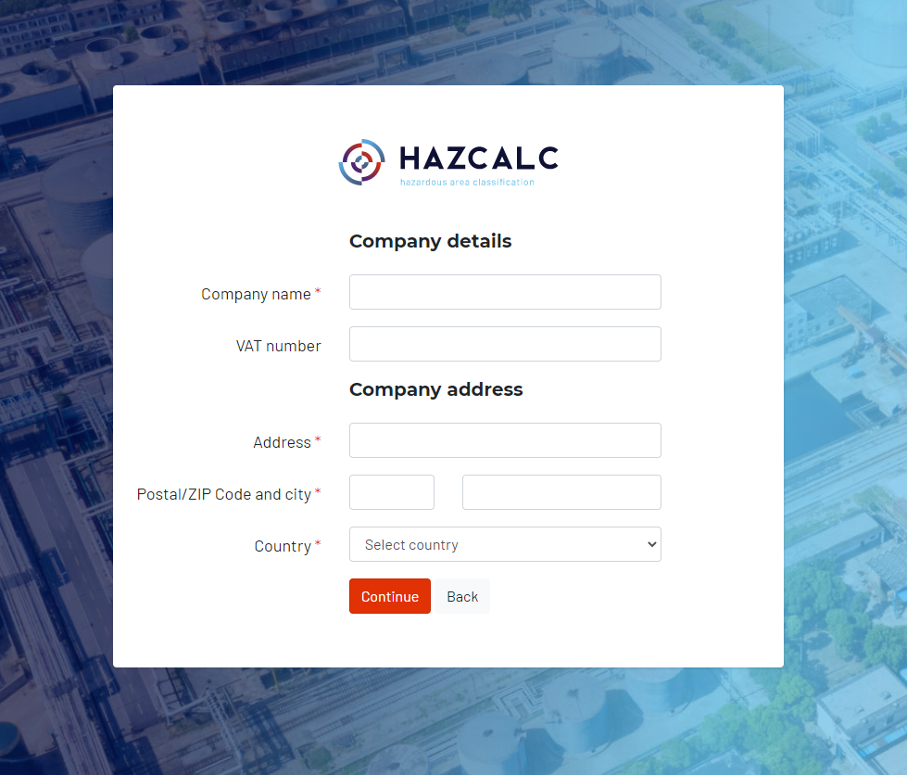

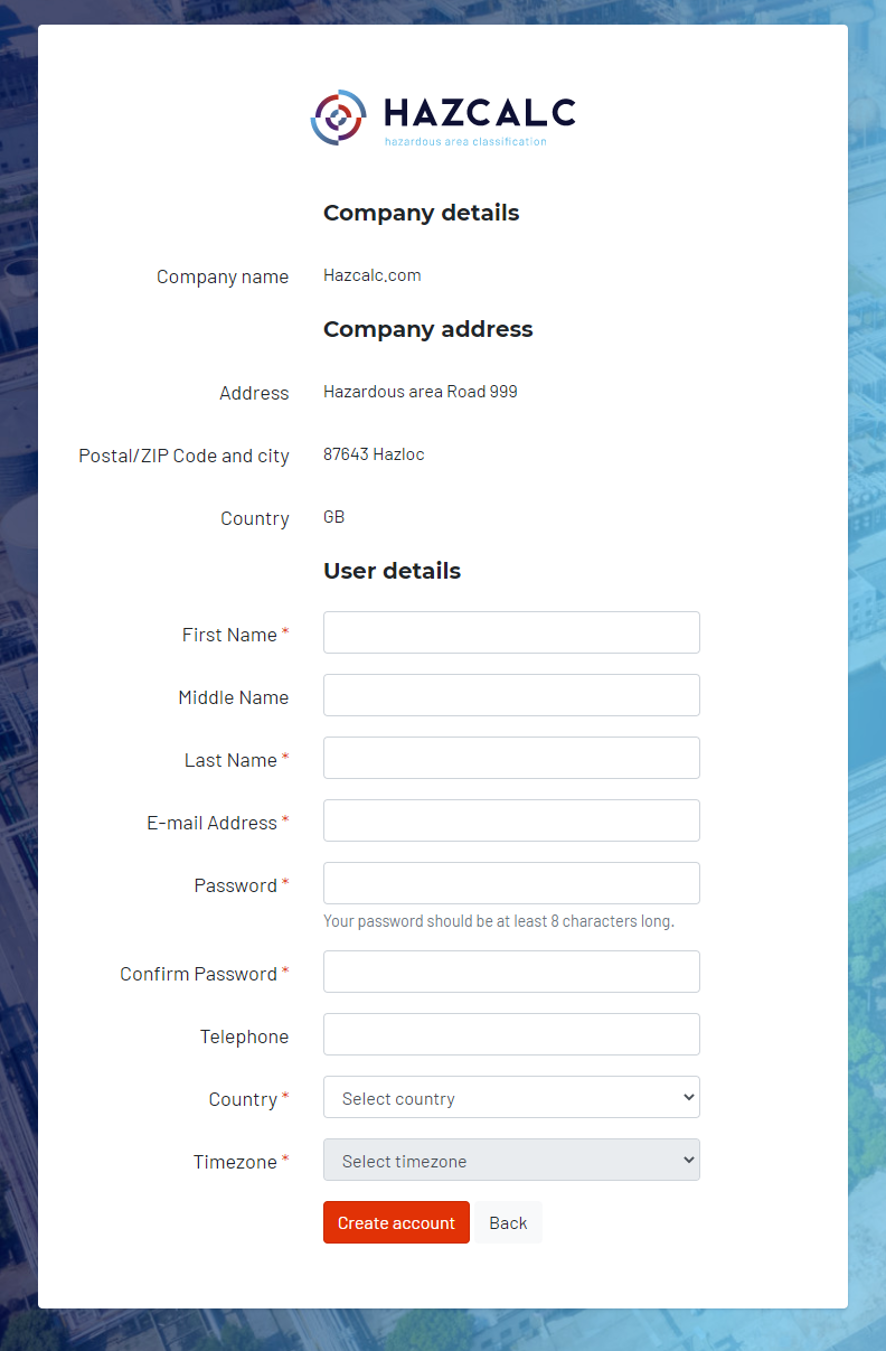

The creation of an account is possible for business users. First of all the company credentials must be added, also when one wants to try the demo version!

After creation of an account, the account must be verified by clicking the link in the automated email that you received.

So now you are able to user the benefits of Hazcalc, so login with your email address and password.

2.2 Demo account

After creating a demo account, a 4-week free demo trial of Hazcalc starts! This is free of charge and after 4 weeks the tool is automatically blocked.

With a demo account the full possibilities of Hazcalc can be experienced. Several demo assessments are available and one can click through the pages and field. Values can be edited and reports can be printed.

In the demo version it is not possible to store assessments and see the results of own made calculations. Therefor you need a paid subscription.

2.3 Paid user account

During the use of the demo version or after expiring of the demo version a full license can be purchased. This can be done within the profile settings of your account. We offer multiple user plans. More information on our user plans are on our website hazcalconline.com.

2.3.1 Single user account

A single user account is an account that strickly belongs to the user who made the account.

2.3.2 Multiple users account

A multiple user account is a bussiness account with more than 1 user. This gives high flexibility, because users can be removed and added by a company-administrator and the company-administrator is able to login as a specific user.

3 Structure of the application

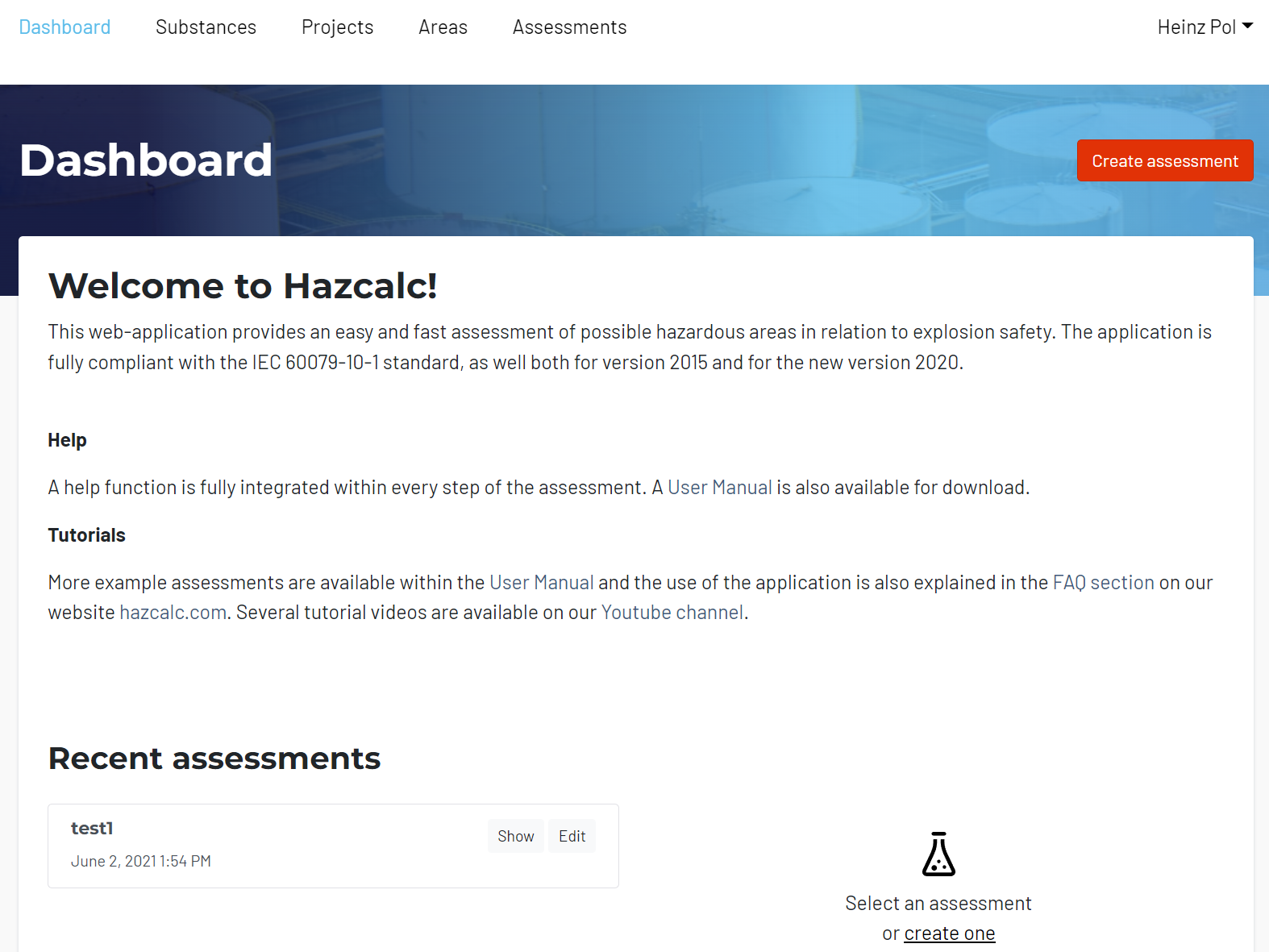

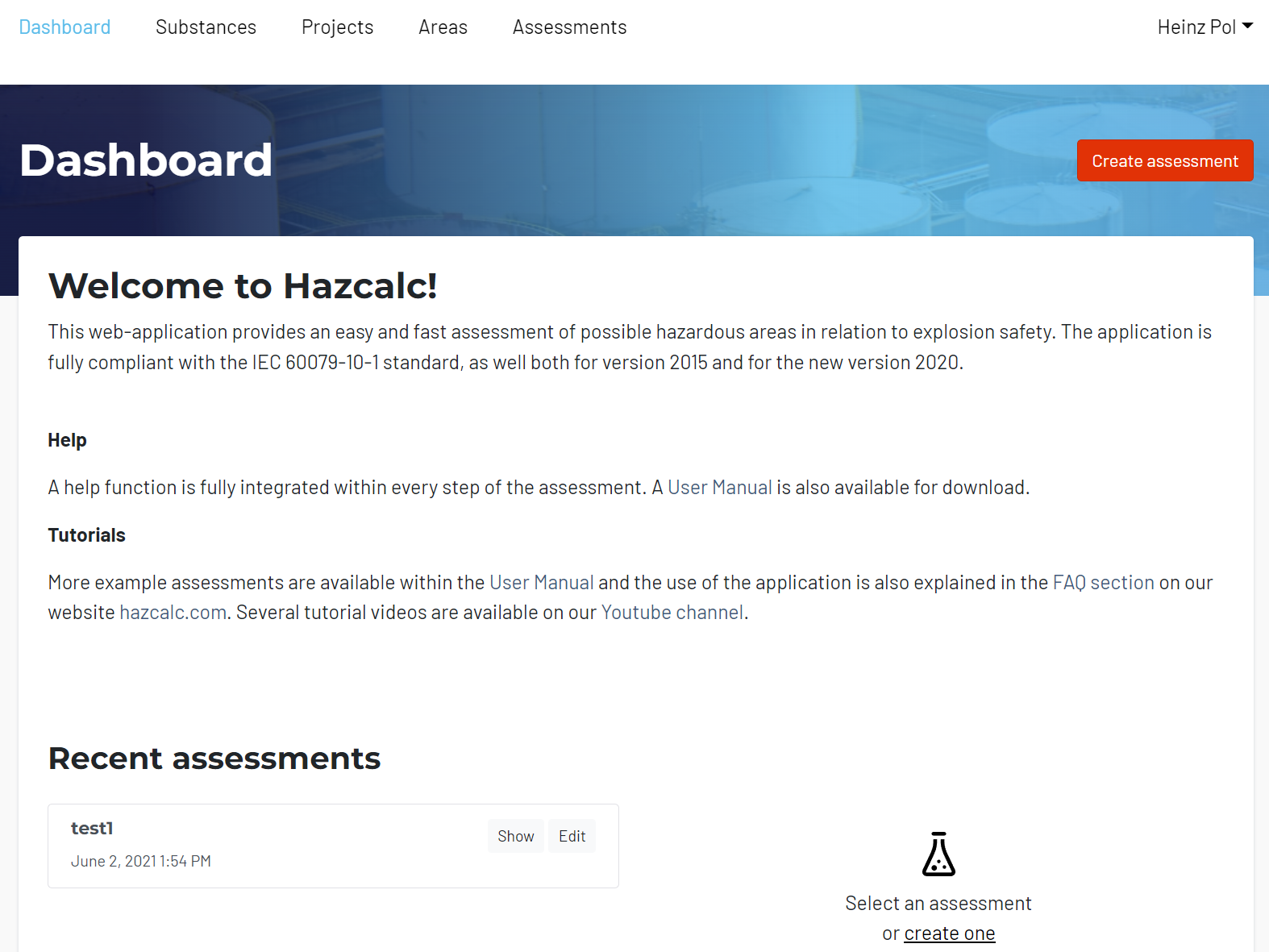

After login the Dashboard screen is opened with presented all resent assessments (or empty for new users).

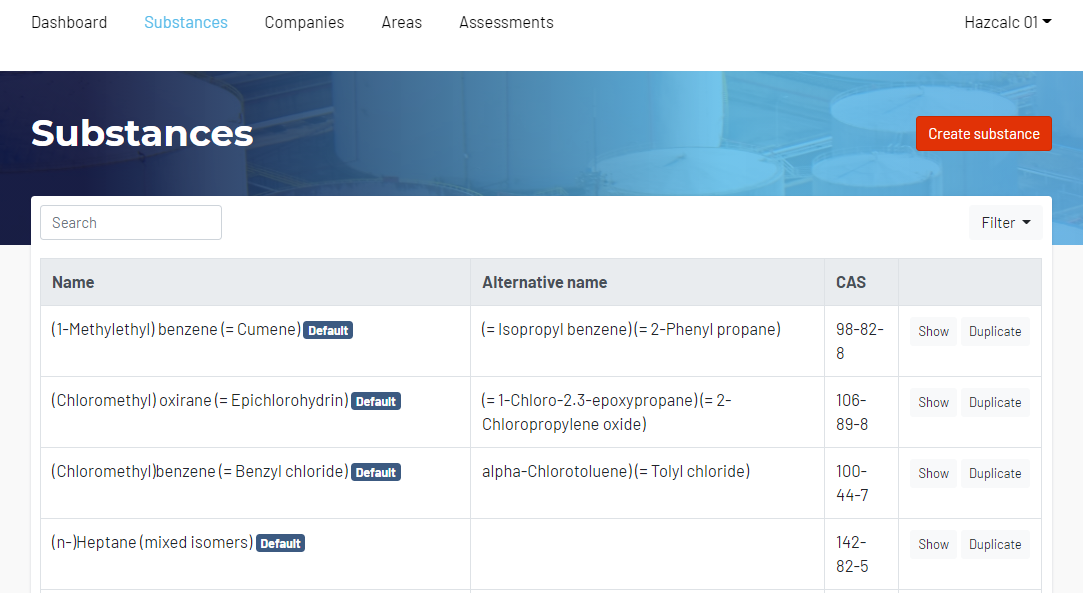

3.1 Substances

A default database of more than 250 substances is integrated within the application. These substances come from the IEC 60079-20-1 standard (Explosive Atmospheres - Part 20-1: Material characteristics for gas and vapour classification - Test methods and data). These substances cannot be edited or removed.

3.1.1 Selecting and checking

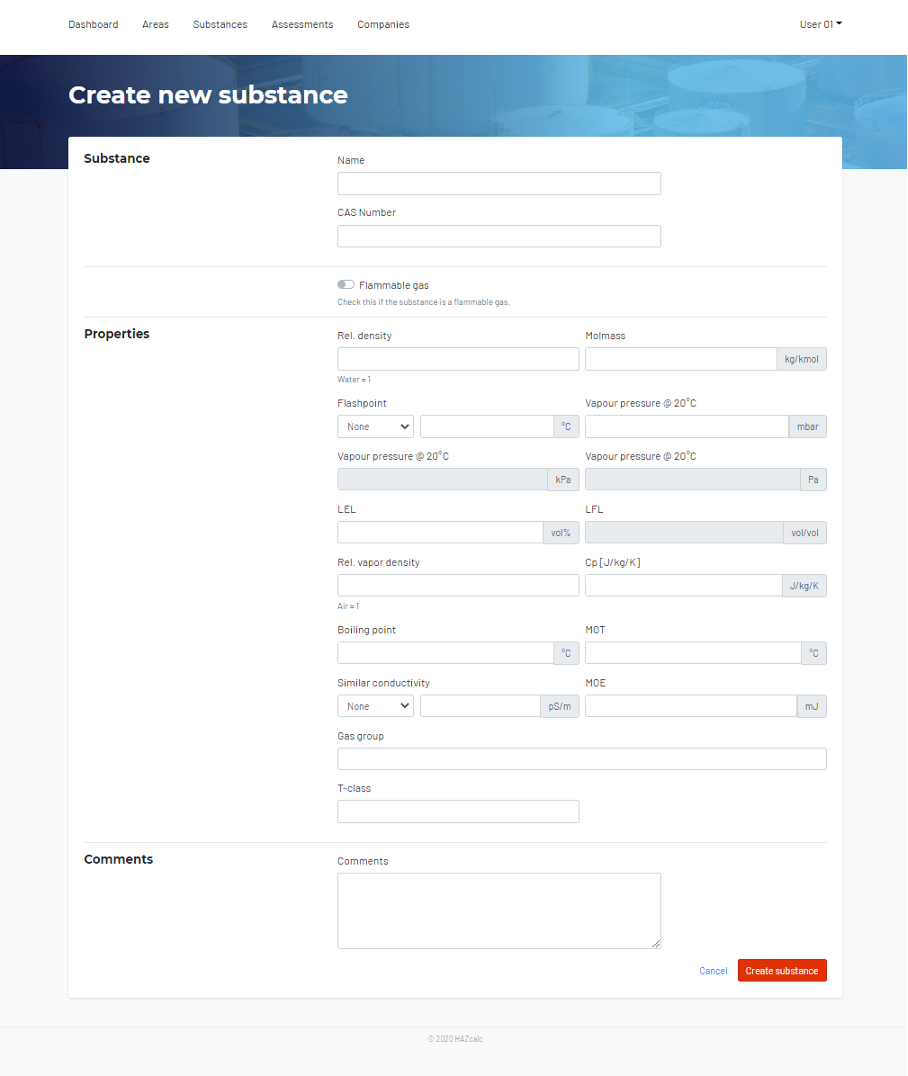

3.1.2 Manual adding substances

When the substance is not within the pre-defined substance database, new substances can be added by the user. These user defined substances are only available within the account of the user that added the new substance.

For adding new substances we recommend the following data sources:

- GESTIS Substance Database:

https://www.dguv.de/ifa/gestis/gestis-stoffdatenbank/index-2.jsp - NIST Chemistry WebBook:

https://webbook.nist.gov/chemistry/#

Other data sources can also be used.

Mandatory* parameters are:

- Name

- Molmass

- Vapour pressure @ 20 °C (only for liquids)

- LEL

- Rel. vapor density

- Only for flammable gas: Cp

After entering the data click “create substance” to add the substance to the database! The substance can now be selected within the assessment.

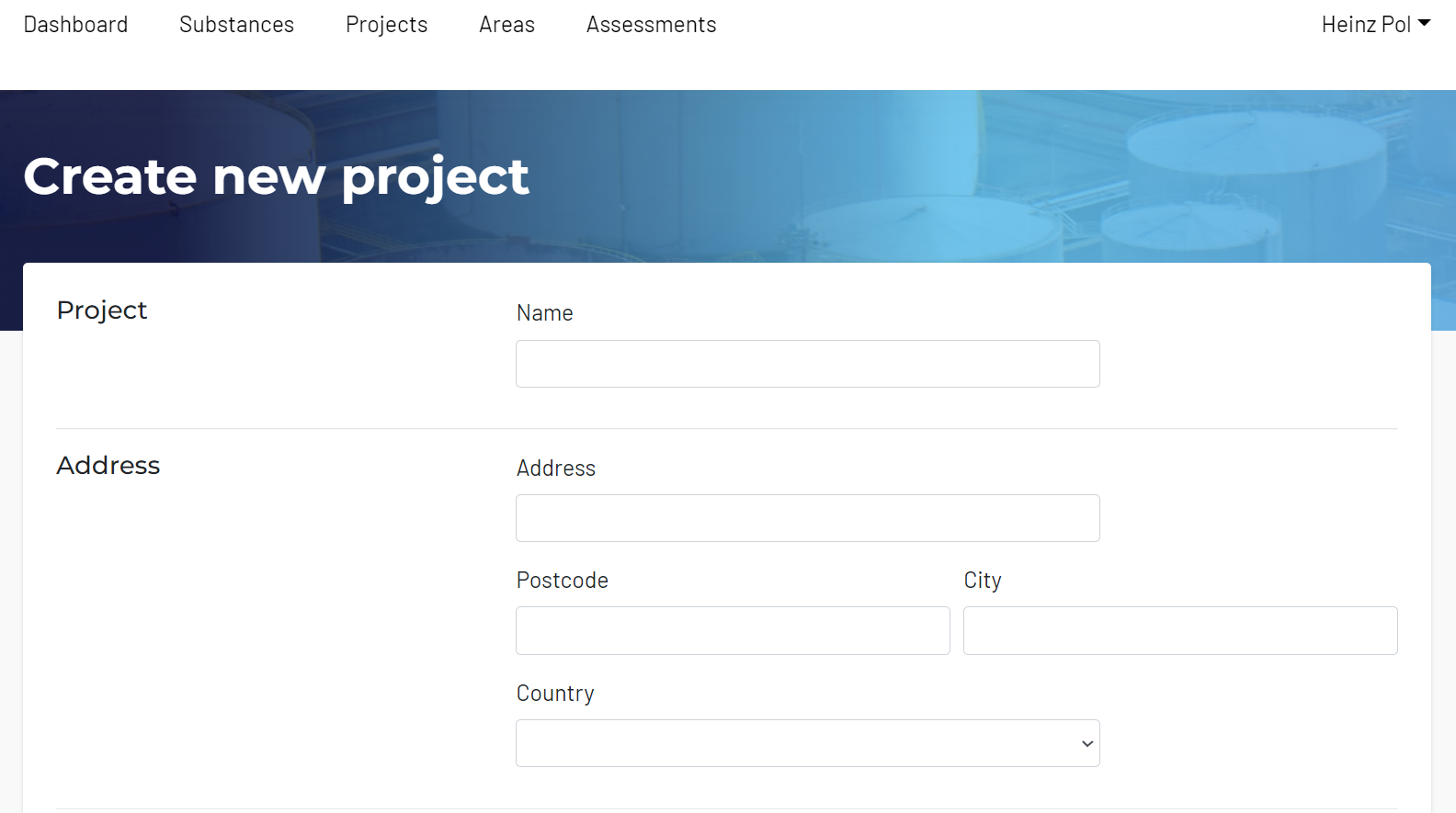

3.2 Projects

Before starting an assessment the related project or company must be added to the application. Mostly it is the company where the assessment is related to, like a client or customer or your own workplace. Only the Project name is mandatory, but also all other fields can be filled in.

3.3 Areas

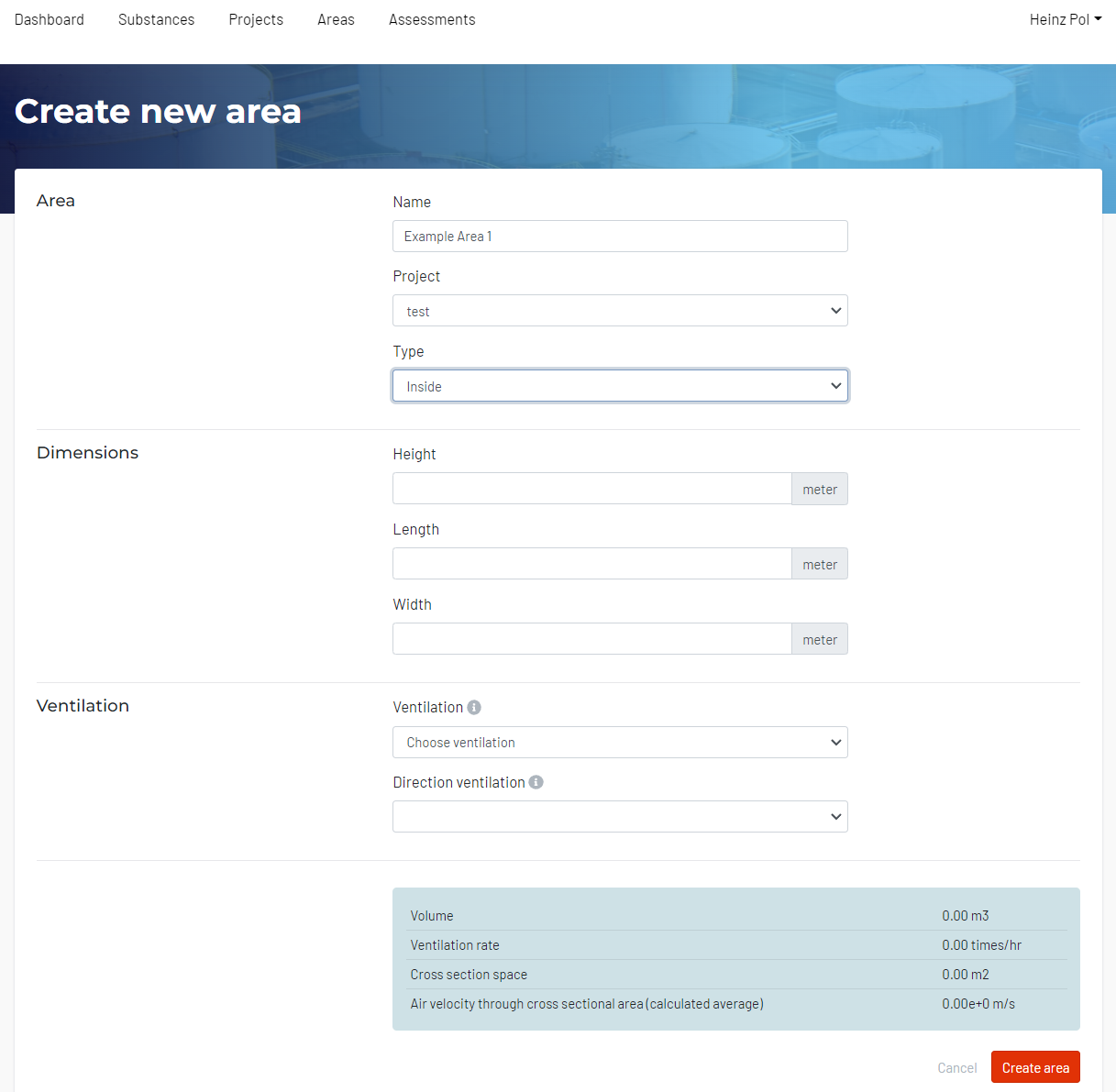

- For making assessment of indoor situations, areas must be added to the system.

- For making assessments of outdoor situations, definition of areas can be beneficial in order to sort or filter on area's within the assessments overview page. For outdoor situations, the definition of outdoor area's is not mandatory.

3.3.1 Name and dimensions

For indoor situations also the dimensions of the area must be specified.

When an area is not a rectangle, but maybe round or in other forms, specify the average length, width and height! These dimensions are used for automated calculation of the air velocity and ventilation rate. The calculated average airvelocity within the area is a good indication.

The average calculated airvelocity within the area under consideration can always be overridden in the actual assessment with a value that is more accurate (e.g. measured with an airvelocity measuring device).

3.3.2 Ventilation

The type of ventilation within the area must be specified here:

- Mechanical

- Natural

- Mechanical + Natural

For each type of ventilation the ventilation capacity must be added. For mechanical ventilation capacity, check the installation manuals or perform ventilation measurements. For natural ventilation capacity check the IEC 60079-10-1 standard for calculation purposes or perform ventilation measurements.

Be sure that the ventilation properties are added well, because these parameters are quite significant within the model. However, the air velocity can also be overridden within the model at the relevant positions.

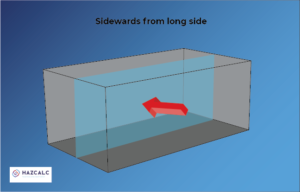

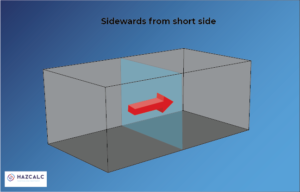

For automated calculation of the air velocity one has to choose the direction of the ventilation. In this way an average air velocity through a cross-sectional area of the room will be calculated. Manual override of this calculated value is also still possible at the relevant positions within the model.

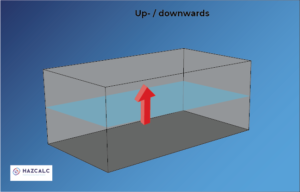

Direction of ventilation

Select the most appropriate direction of the ventilation according to these pictures:

Sidewards - long side

Sidewards - short side

Up-/downwards

Based on this input, the model automatically calculates the cross sectional area across the space under considoration and uses that value for calculating the average air velocity through the area. As mentioned, this value can still be overridden at the appropriate places within the assessment-model.

4 How things work!

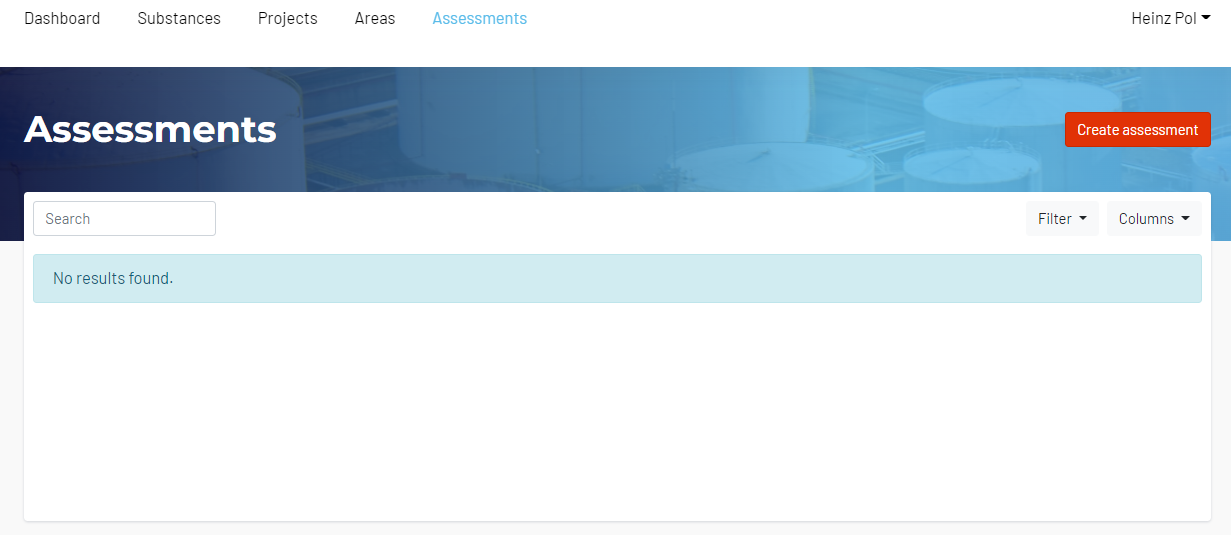

After entering the applicable substances, projects and areas, a new assessment can be performed by clicking “Create assessment”

After clicking “Create Assessment” the following screen shows up:

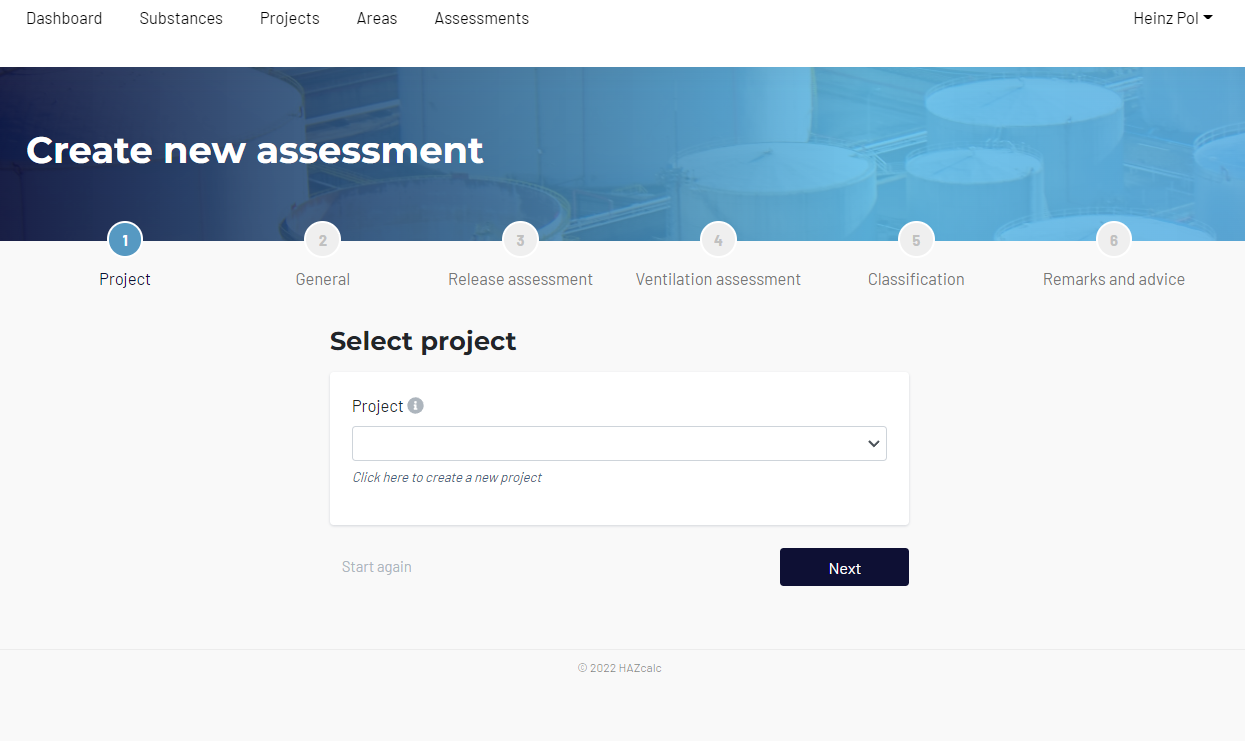

4.1 Assessment in 7 steps

Here you can see that an assessment is divided in 7 steps:

- Project

- General

- Release assessment

- Ventilation assessment

- Classification

- Remarks and Advice

- Report

Each step in de assessment-process can be followed up by clicking next.

4.1.1 Select Company

First of all a company must be selected. Mostly it is the company where the assessment is related to, like a client or customer or your own workplace. When no company can be selected, one has to add a new company first (see chapter 3.2).

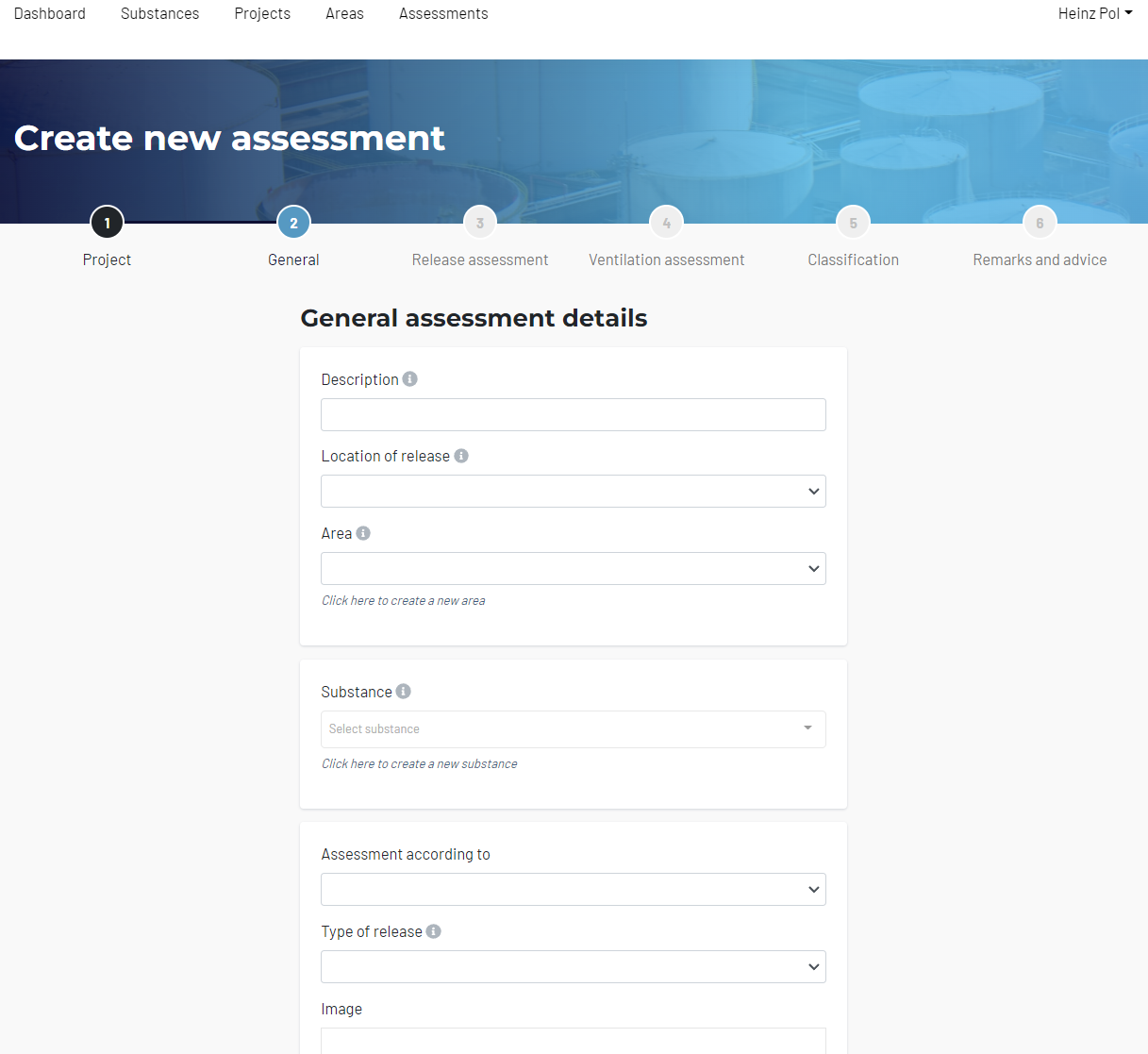

4.1.2 General assessment details

Description

Here one can give a short description of the assessment to be executed.

Location of release

One can select the location of release. For indoor locations, the area must be specified and selected (see chapter 3.3 when the area is not in the list).

Substance

The substance can be selected from the list.

All the relevant data is automatically loaded within the blue fields.

Assessment according to

Select which version of the IEC standard 60079-10-1 must be used; the 2015 or the 2020 version.

Type of Release

At last one has to choose the type of release. With the several types of release the “vapour release rate” must be calculated. The “vapour release rate” stands for the amount of substance (in time) in gaseous form that releases from the source.

Image

An image (max. 25 MB) can be uploaded for displaying in the assessment-report.

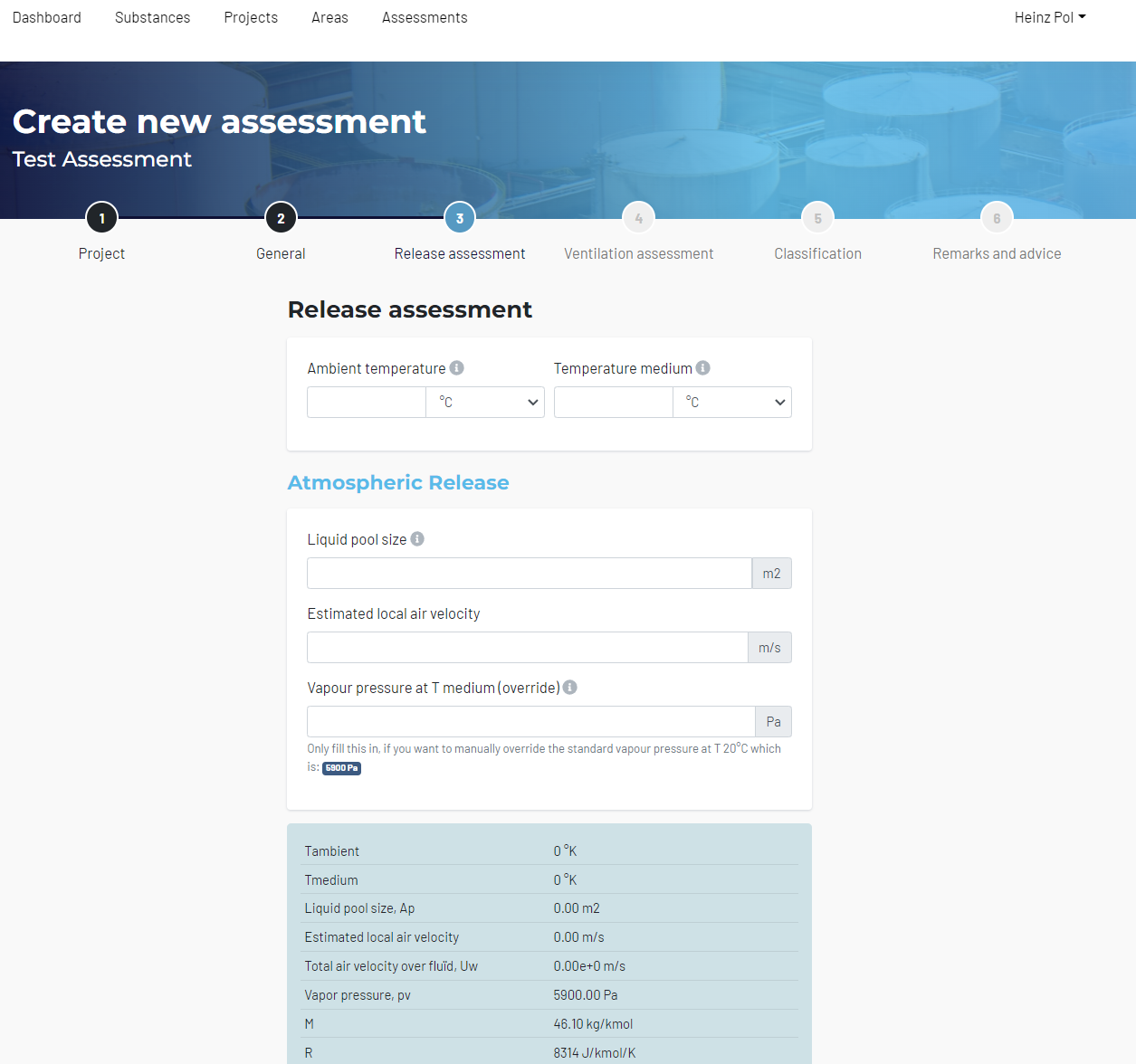

4.1.3 Release Assessment

| General | |

| Ambient temperature | The temperature of the room or area under consideration.

|

| Temperature medium | The temperature of the medium under consideration.

|

| Atmospheric release | |

| Liquid pool size | When liquids are spilled or dripping out of an enclosure, an evaporative pool on the floor will be formed. Estimate the maximum size of that pool. This can be done e.g. by the size of a drip tray that is used or by the maximum time/size before a spill is discovered.Be aware that under-estimation of the size of the pool leads to underestimation of the risk.

|

| Estimation increase air velocity  |

Based on the values entered when creating an area (see chapter 3.3) the average air velocity within the room is calculated. This can be an underestimation of the actual air-velocity across the liquid pool. E.g. local fans of motors or other type of equipment can locally lead to a higher air velocity. The gaseous release rate from the pool depends for a large amount on the used air velocity: the higher the air velocity, the higher the gaseous release rate will be. So within this field a correction on the average calculated air velocity can be made. This can be done by performing measurements of the air velocity above the pool or by an estimation. As a reference one can use the following thoughts: an air velocity of appr. 0,10 m/s can be felt by workers and often leads to complaints.Be aware that under-estimation of the air velocity across the pool leads to underestimation of the risk.

|

| K-factor | The k-factor must be selected for calculating the Release Characteristic. The use of the k-factor is removed with version 2020 of the IEC 60079-10-1. Hazcalc was updated in june 2021, when a Safety Factor was introduced to the IEC 60079-10-1:2020 version model. (in step 4 Ventilation Assesment). The k-factor is a safety factor attributed to the Lower Flammable Limit, typically between 0,5 and 1,0. A lower value however can also be used. This leads to a higher release characteristic and thus a more conservative approach. |

| Manual release | |

| We / Wg | Add evaporation rate of liquids (We) or mass release rate of gas (Wg) manually. This option is available for calculations made that are not available within IEC 60079-10-1.

|

| K-factor | The k-factor must be selected for calculating the Release Characteristic. The use of the k-factor is removed with version 2020 of the IEC 60079-10-1. Hazcalc was updated in june 2021, when a Safety Factor was introduced to the IEC 60079-10-1:2020 version model. (in step 4 Ventilation Assesment). The k-factor is a safety factor attributed to the Lower Flammable Limit, typically between 0,5 and 1,0. A lower value however can also be used. This leads to a higher release characteristic and thus a more conservative approach. |

| Vapour pressure | |

| Speed of the release [m3/hr] |

Add the flow rate of the liquid that is pumped of transported in the enclosure (like an IBC or vessel). The displaced air comes with the same flow rate out of the fill-opening of the enclosure.

|

| Pressure in casing [Pa] |

Specify the pressure within the casing. Normally 101325 Pa.

|

| Vapour pressure at Tmedium (override) |

The standard vapour pressure at 20 °C can be overridden here when the temperature of the medium is higher or lower than 20°C. Use data sources on the internet for reference values. The NIST Chemistry WebBook: https://webbook.nist.gov/chemistry/# can be used for making calculations with the Antoine formula.

|

| K-factor | The k-factor must be selected for calculating the Release Characteristic. The use of the k-factor is removed with version 2020 of the IEC 60079-10-1. Hazcalc was updated in june 2021, when a Safety Factor was introduced to the IEC 60079-10-1:2020 version model. (in step 4 Ventilation Assesment). The k-factor is a safety factor attributed to the Lower Flammable Limit, typically between 0,5 and 1,0. A lower value however can also be used. This leads to a higher release characteristic and thus a more conservative approach. |

| Liquid release | |

| Atmospheric pressure [bara] |

Fill in the atmospheric pressure; normally 1 bar absolute.

|

| Pressure in system [barg] | Fill in the pressure within the enclosed system. Check manometers (bar gauge) for reference values.

|

| S | Cross section of the opening (hole), through which the fluid is released (mm2) Specify the release opening. See table B.1 in IEC 60079-10-1 for suggested hole cross sections for secondary grades of release. See also the help function within the application. Be aware that under-estimation of this release opening leads to underestimation of the risk.

|

| Cd | Specify the value of Cd, discharge coefficient (dimensionless) which isva characteristic of the release openings and accounts for the effects of turbulence and viscosity, typically 0,50 to 0,75 for sharp orifices and 0,95 to 0,99 for rounded orifices.

|

| Percentage evaporation | Fill in the percentage of the liquid that evaporates immediately after release. Normally this is an estimation. Be aware that under-estimation of this percentage leads to underestimation of the risk.

|

| K-factor | The k-factor must be selected for calculating the Release Characteristic. The use of the k-factor is removed with version 2020 of the IEC 60079-10-1. Hazcalc was updated in june 2021, when a Safety Factor was introduced to the IEC 60079-10-1:2020 version model. (in step 4 Ventilation Assesment). The k-factor is a safety factor attributed to the Lower Flammable Limit, typically between 0,5 and 1,0. A lower value however can also be used. This leads to a higher release characteristic and thus a more conservative approach. |

| Pressurized release | |

| Atmospheric pressure | Fill in the atmospheric pressure; normally 1 bar absolute.

|

| Pressure in system | Fill in the pressure within the enclosed system. Check manometers (bar gauge) for reference values.

|

| S | Cross section of the opening (hole), through which the gas is released (mm2).Specify the release opening. See table B.1 in IEC 60079-10-1 for suggested hole cross sections for secondary grades of release.See also the help function within the application.

Be aware that under-estimation of this release opening leads to underestimation of the risk.

|

| Z | Compressibility factor (dimensionless) The compressibility factor for ideal gases is 1,0. For the real gases, the compressibility factor takes values below or above 1,0 depending on type of the gas concerned, the pressure and the temperature. For low to medium pressures, Z =1,0 can be used as a reasonable approximation and may be conservative. For higher pressures, e.g. above 50 bar, and where improved accuracy is required the real compressibility factor should be applied. The values for compressibility factor can be found in data books for gas properties. |

| Cd | Specify the value of Cd, discharge coefficient (dimensionless) which is a characteristic of the release openings and accounts for the effects of turbulence and viscosity, typically 0,50 to 0,75 for sharp orifices and 0,95 to 0,99 for rounded orifices. |

| k-factor | The k-factor must be selected for calculating the Release Characteristic. The use of the k-factor is removed with version 2020 of the IEC 60079-10-1. Hazcalc was updated in june 2021, when a Safety Factor was introduced to the IEC 60079-10-1:2020 version model. (in step 4 Ventilation Assesment). The k-factor is a safety factor attributed to the Lower Flammable Limit, typically between 0,5 and 1,0. A lower value however can also be used. This leads to a higher release characteristic and thus a more conservative approach. |

| Cp (override) | Specific heat at constant pressure (J/kg K). This value depends on the temperature of the medium. So with higher medium temperatures, the specific heat can be adjusted here. Use data sources on the internet for reference values.The NIST Chemistry WebBook: https://webbook.nist.gov/chemistry/# can be used by making correction based on interpolation. |

4.1.4 Ventilation Assessment

Within the ventilation assessment the degree of dilution of the flammable gases / vapours in the atmosphere (calculated within the release assessment in the previous step) are assessed.

The principle is that a high degree of dilution of gases / vapours leads to a lower concentration of the flammable substances in the atmosphere; thus a lower potential risk. A lower degree of dilution however, leads to less dilution of gases/ vapours and thus to a higher potential risk.

The degree of dilution is equal to the air velocity near the source of release. The higher the air velocity, the more dilution of vapours and gases. The lower the air velocity, the less dilution. The air velocity near the source of release is compared with the characteristic of the release. The characteristic of the release is the ratio between the calculated evaporation rate of liquids or the release rate of gases and a percentage (k-factor) of the Lower Flammable Limit.

The following fields must be entered within the ventilation assessment:

| Ventilation Assessment | |

| Airvelocity for Dilution

|

The air velocity for dilution must be entered. Two scenarios are available:

For indoor situations: This can be an underestimation of the actual air-velocity for dilution within the room and near the source of release. So within this field the average calculated air velocity can be overrided. Be aware that over-estimation of the air velocity near the source of release leads to underestimation of the risk! For outdoor situations:

|

| Background Concentration | For indoor situations, also another factor must be calculated: the background concentration. The background concentration within an area may never reach the critical concentration. The critical concentration is specified as 25% of the Lower Flammable Limit of a substance. This can be explained by the following example: a high air velocity within the vicinity of the source of release can be achieved by a local ventilator. The air velocity can be extremely high there, so locally the flammable substances will be diluted with a high grade. Over time however, the average concentration of flammable substances within the room can, in case of a low ventilation capacity (m3/hr) of the room, rise to a dangerous level. In that case the grade of dilution is set to low, and a potential high risk can be present. For assessing the background concentration the following field must be entered: |

| Efficiency ventilation | The efficiency of the ventilation has only to be entered for indoor situation where the background concentration has to be assessed.

The efficiency of the ventilation (factor f in the IEC standard) stands for the efficiently of the ventilation within the room related to the average The efficiency of the ventilation within the room is classified as a number from 1 to 5: 1 stands for efficiently mixing of the air within the total area The factor is used for assessing the background concentration within the area under consideration. This concentration may not be higher than a Within Hazcalc this value is fixed at 25% of the LFL. Tip:

|

| Availability of the ventilation | The availability of the ventilation must be classified. IEC 60079-10-1 specifies 3 levels:

Different types of ventilation require different approaches for assessing their availability, e.g. availability of natural ventilation indoors shall never be considered as good because it depends heavily upon ambient conditions, i.e. outdoor temperature and wind. See C.3.7.1 of IEC 60079-10-1:2020 for more guidance. Tip:

|

| Safety Factor | With reference to the 2020 version of the IEC-standard, a safety factor was introduced within Hazcalc. This Safety Factor is an extra factor that can be applied for assessing the Ventilation. The applied factor is a safety factor in relation to the Lower Flammable Limit, e.g. when a safety factor of 25% is applied, the Release Characteristic is calculated based on a LFL of 100%-25% = 75% of the Lower Flammable Concentration.

With a Safety Factor of 10%, the Release Characteristic is calculated with 90%LFL. When using this factor, one will see that this factor can be critical when the red dot in the graphs in near to the blue or red line, so that another dilution class must be applied. |

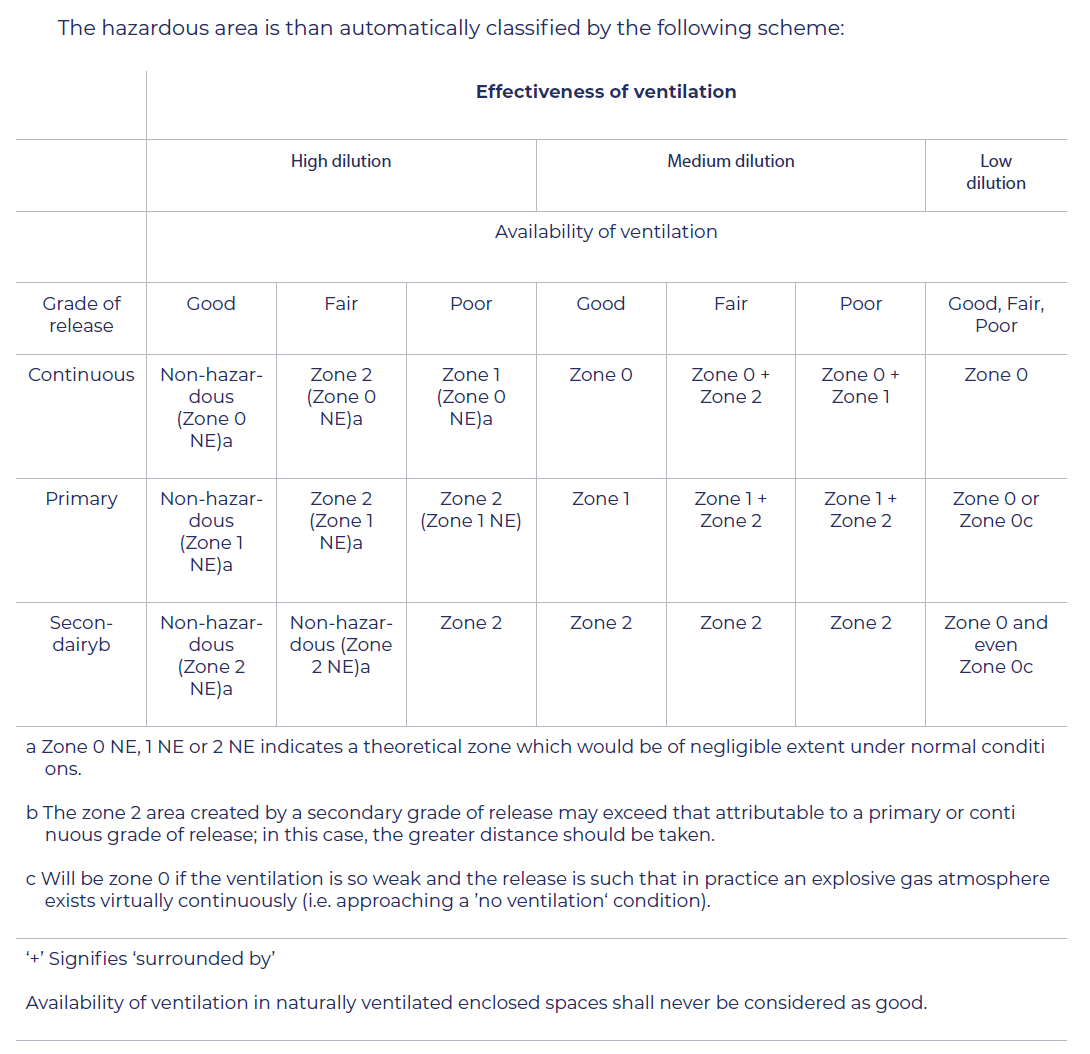

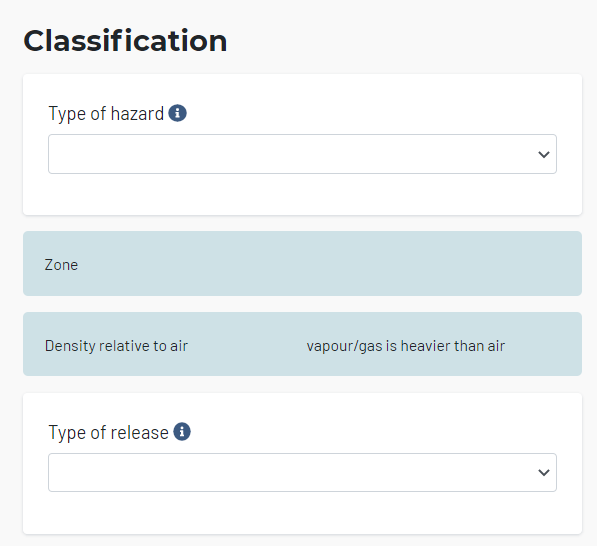

4.1.5 Classification

The classification of hazardous areas is determined by the result of all the input from the previous steps together with the type of release source (type of hazard) and the type of release.

Type of release source

The source at which a substance is released has to be classified as type of release source. The following types of release source are applicable:

- Continuous source of release;

- Primary source of release;

- Secondary source of release.

These types of release are defined as (within IEC 60079-10-1):

| Type of Hazard | |

| Continuous grade of release

|

Which is continuous or is expected to occur frequently or for long periods

Examples are:

Note: in some national standards a percentage of the working time or operational time of the installation is set as a “rule of thumb”: more than 10% of the duration of an activity or more than 10% of the operational time of the installation.

|

| Primary grade of

release |

Release which can be expected to occur periodically or occasionally during normal operation

Examples are:

Note: in some national standards a percentage of the working time or operational time of the installation is set as a “rule of thumb”: between 0,1 and 10% of the duration of an activity or between 0,1 and 10% of the operational time of the installation.

|

| Secondairy grade of

release |

Release which is not expected to occur in normal operation and, if it does occur, is likely to do so only infrequently and for short periods

Examples are:

Note: in some national standards a percentage of the working time or operational time of the installation is set as a “rule of thumb”: less than 0,1% of the duration of an activity or less than 0,1 % of the operational time of the installation.

|

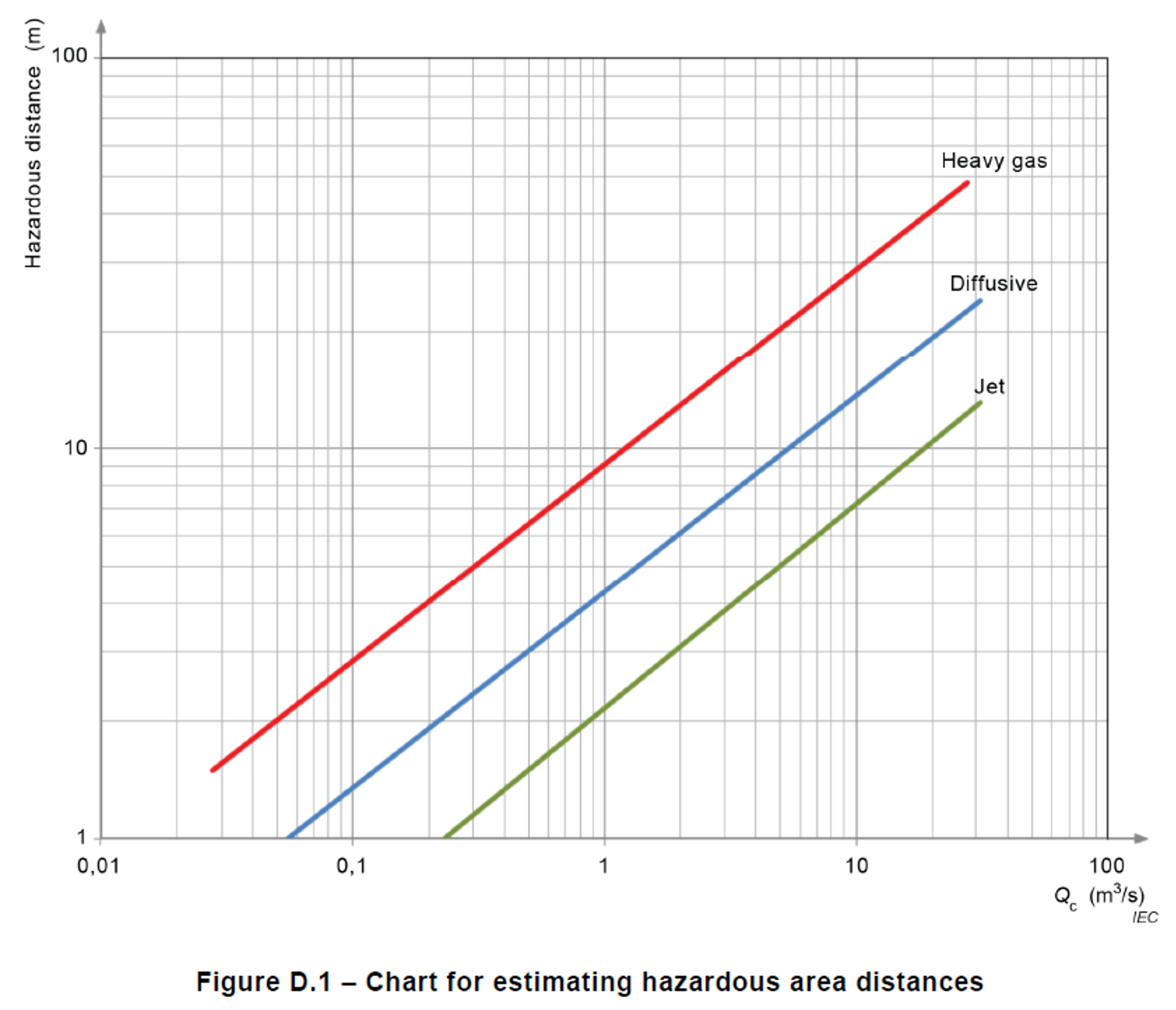

Extend of the hazardous area

The extent of the hazardous zone or region where flammable gas may occur depends on the release rate and several other factors such

as gas properties and release geometry and surrounding geometry.

Figure D.1 in the standard may be used as a guide to determine the extent of hazardous zones for various forms of release.

The appropriate line from the graph should be selected based on the type of release as either:

- an unimpeded jet release with high velocity;

- a diffusive jet release with low velocity or a jet that loses its momentum due to the geometry of the release or impingement on nearby surfaces;

- heavy gases or vapours that spread along horizontal surfaces (e.g. the ground).

Possible guidance on selecting the type of release:

| Type

|

Should be selected when: |

| Jet | Assessing pressurized gas systems.

|

| Diffuse | Assessing (low) pressurized gas systems and liquid evaporation

|

| Heavy | Assessing (low) pressurized gas systems and liquid evaporation from substances that are heavier than air (e.g. substances with a relative density higher than 1,2). |

In IEC 60079-10-1:2015 the Volumetric release characteristic of the source, Qc, on the horizontal axis, was defined as the Release characteristic Wg/ρg x k x LFL.

Further the graph is exact the same is in IEC 60079-10-1:2020. Within Hazcalc the graph from the 2020 version is used.

The curves are based on a zero background concentration and are not applicable for indoor medium and low dilution situations (see C.3.6.1).

The chart represents a rough approximation for some large-scale situations but would not be reliable on a small scale level. Where a zone of negligible extent (NE) is suggested then the use of this chart is not applicable.

4.1.6 Remarks, Advice

Within these two fields some comments can be

made and an advice can be given on which hazardous

area and which extent of the hazardous area

should be applied.

The fields are not mandatory but can give more

explanation about the basic principles or starting

points, thoughts and considerations that are applicable

on the assessment.

4.1.7 Finish

Click Finish to save the assessment. The total assesment

is displayed on screen now, so control of all the values is easy.

4.1.8 Report

The assessment can be printed as an Acrobat PDF file with the Report button.

Multiple assessments can be printed in one report by selecting the assessments on the “Assessments page and select Report.

On IOS Devices one must click on “Click here to try again”in order to open the pdf on screen.

TIP: When printing multiple assessments at once, the assessments are ordered by the description.

5. Edit Assessments

On the assessment page, all the assessments are stored. Useful features here are the filter options to display only certain sets of assessments, e.g. to compare certain assessments and its results.

5.1 Showing Assessments

By clicking on show the report of the assessment is shown.

5.2 Editing Assessments

By clicking edit, the selected assessment can being edited. This can be done by clicking on the appropriate chapter, changing the values and clicking next and in step 7 on Finish.

5.3 Deleting Assessment

By clicking delete the selected assessment will be deleted from the database.

5.4 Copy Assessment

By clicking copy, the selected assessment will be copied. The name will be added with the suffix copy_xx. This option is very useful for quick adding or comparison of e.g. identical situations where only the substance changes, or what the effects are of more ventilation in a given circumstance.

6. Used formulas

The formulas used for the calculations are mainly based on the formulas stated in the IEC 60079-10-1 standards.

However, for the “Vapour Pressure” type of release a formula is used from another source: Chemiekaarten (Chemical Cards):

C = M/22,4 x p/1013 x 273/T x 10^6, where

C = concentation in air in mg/m3

M = molecule mass

p = vapour pressure in mbar @ temperature T

T = Temperature in Kelvin

Together with the filling rate in m3/hr the mass release rate of (saturated) gas out of the tank opening is calculated. This is a concervative approuch of the actual situation and thus the risk. The actual concentration will be lower, but hard to measure with e.g. a LEL measuring device which stops at appr. 100%LEL.

7. Frequently Asked Questions

Answers about the use of the tool can be found under the Frequently Asked Questions section on the website hazcalconline.com/faq. Also several examples of scenario assessments are available on the website.

When appropriate answers are not listed in the FAQ, a ticket for guidance can be sent to us from your user account. We will answer that ticket as soon as possible.

8. Development

Hazcalc will stay under continuous development. So tips, tricks, feedback and recommendations are welcome.

These can be sent to [email protected]

9. Examples

For the maximum return of investment, several examples of assessments are included within this manual:

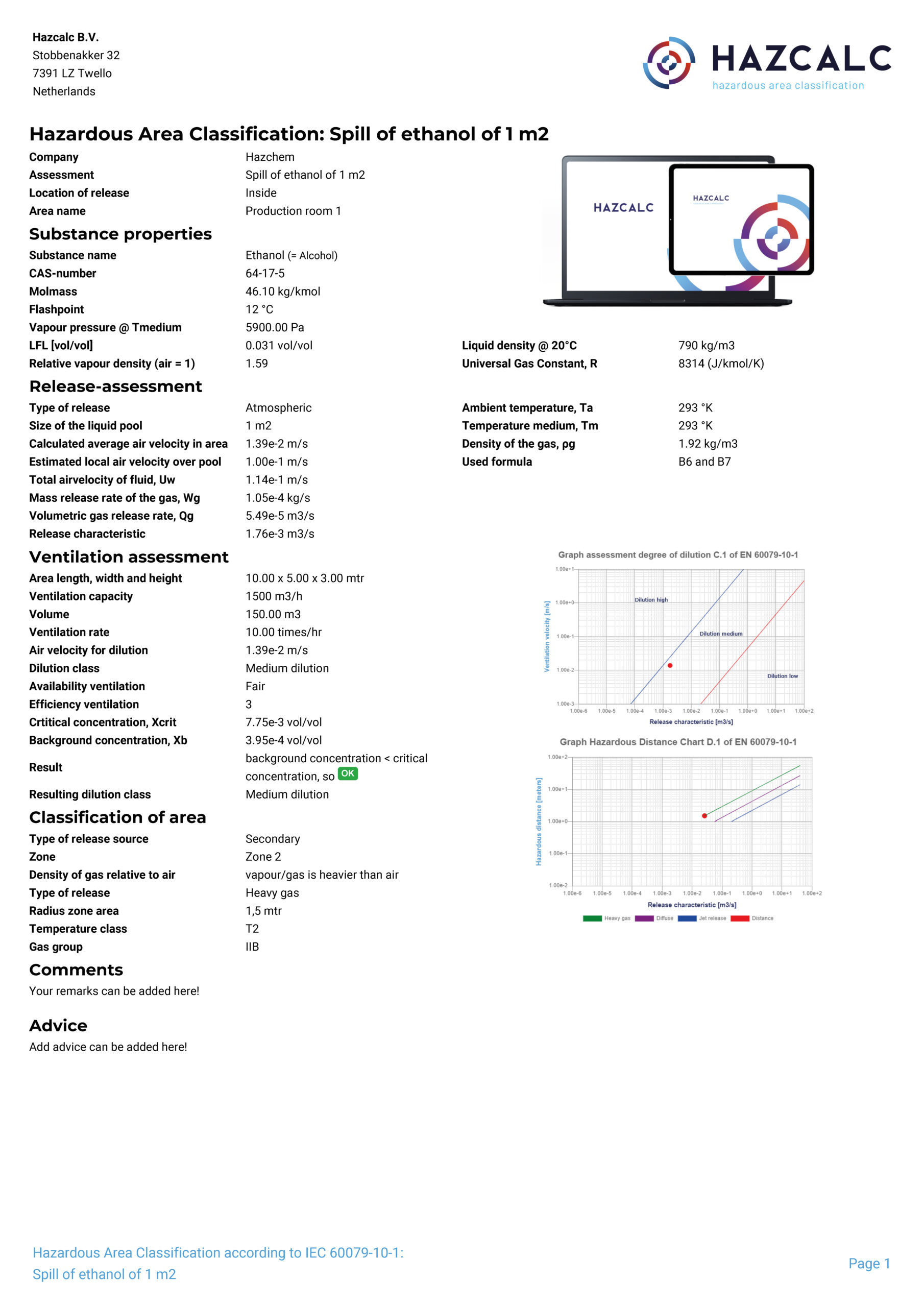

Example 1: Spill of 1 m2 of ethanol within an production facility

Example 2 : Leaking of a flange of a pressurized gas system with hydrogen

Example 3 : Filling an IBC with acetone at a flow rate of 100 ltr/min

Example 4 : Leaking flange of a biogas system ( 40 mbarg) in outdoor situation

Example 5 : Leaking of a pump seal for xylene in an indoor situation

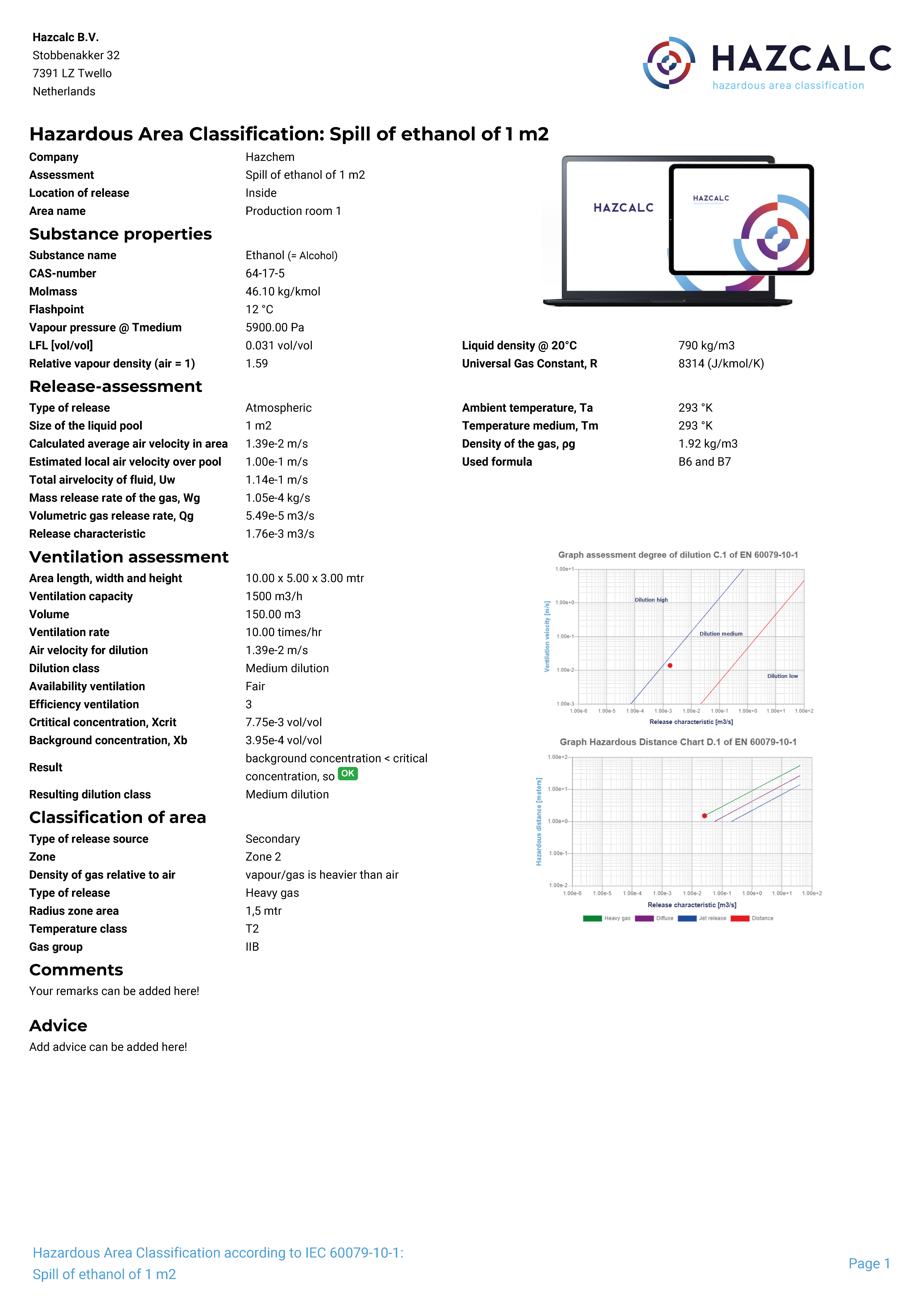

Example 1 Spill of 1 m2 ethanol indoors

Area parameters:

Length : 10 mtr

With: 5 mtr

Height: 3 mtr

Ventilation: Mechanical

Ventlation Capacity: 1500 m3/hr

Direction of ventilation: sidewards long

Ventilation measurements are not performed.

Step 1) Add a project, you can choose the name

Step 2) Add the area with the parameters specified above

Step 3) Start an Assessment for an indoor situation and select the area and the substance from the database, select Edition 2015 and choose as Type of Release: “Atmospheric”

Step 4) Set the temperatures to 20°C, liquid pool size to 1 m2 and estimation increase airspeed to 0,1 m/s

Step 5) Don’t use the dilution override and set the efficiency of the ventilation to moderate (3) and set the availability to “Fair”

Step 6) Select a secondary release source and since the gas is heavier than air choose : “Heavy Gas”

Step 7) Click next, followed by “Finish” and print the report

The result is this report:

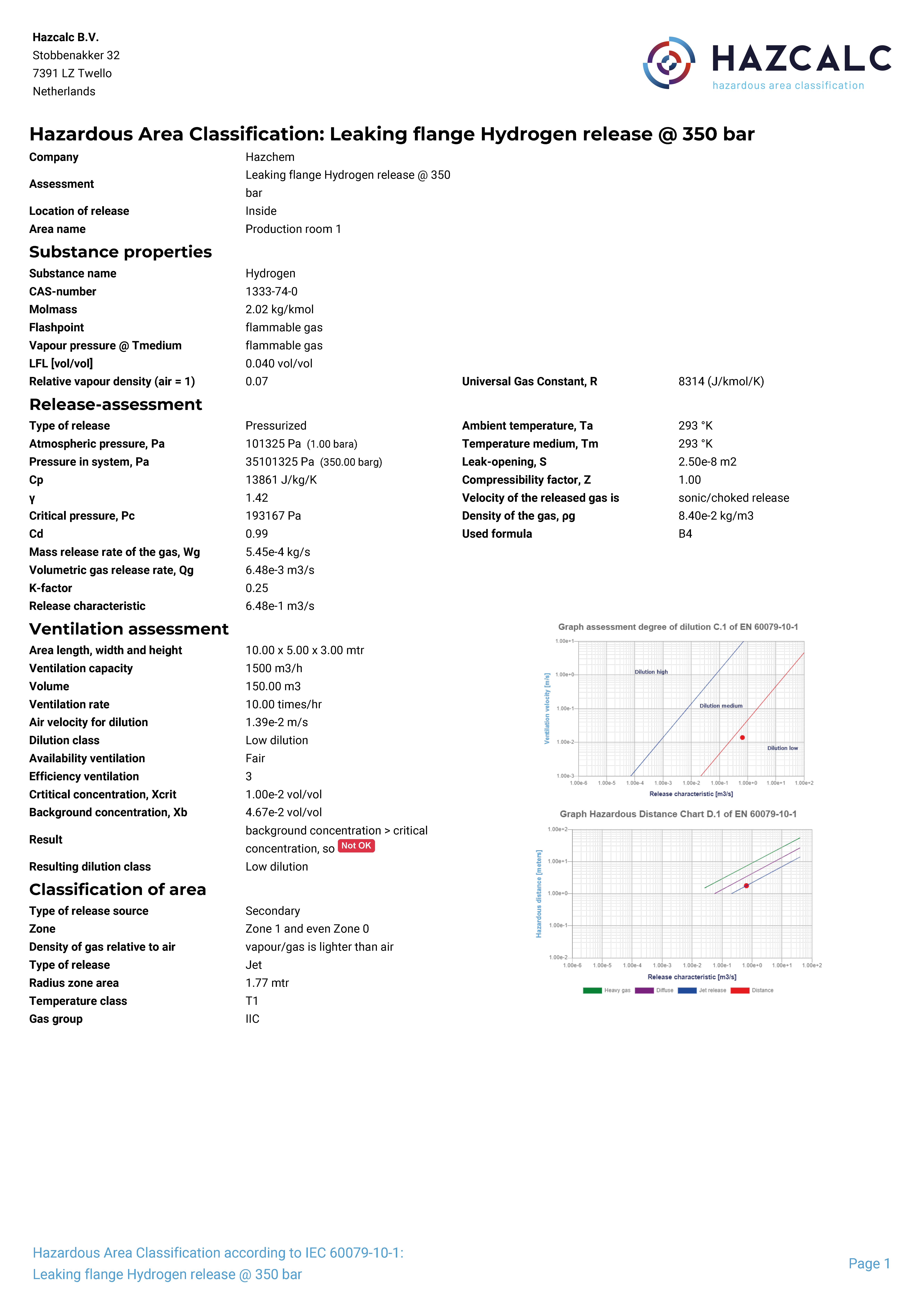

Example 2 Leaking of a flange of a pressurized gas system with hydrogen

Area parameters:

Length : 10 mtr

With: 5 mtr

Height: 3 mtr

Ventilation: Mechanical

Ventlation Capacity: 1500 m3/hr

Direction of ventilation: sidewards long

Ventilation measurements are not performed.

Step 1) Add a Project, you can choose the name

Step 2) Add the area with the paremeters specified above

Step 3) Start an Assessment for an indoor situation and select the area and the substance from the database, select Edition 2015 and choose as Type of Release: “Pressurized”

Step 4) Set the temperatures to 20°C, Atm. pressure to 1 bar and Pressure in system to 350 bar. Select S = 0,025 mm2, Z = 1,0, Cd = 0,99 and don’t use Cp override. Set the k-factor to 0,25.

Step 5) Don’t use the dilution override and set the efficiency of the ventilation to moderate (3) and set the availability to “Fair”

Step 6) Select a secondary release source and since the gas comes out of the release source under pressure, slect “Jet release””

Step 7) Click next, followed by “Finish” and print the report

The result is this report:

Example 3 Filling an IBC with acetone at a flow

rate of 100 ltr/min

Area parameters:

Length : 10 mtr

With: 5 mtr

Height: 3 mtr

Ventilation: Mechanical

Ventlation Capacity: 1500 m3/hr

Direction of ventilation: sidewards long

Ventilation measurements are not performed.

Step 1) Add a project, you can choose the name

Step 2) Add the area with the parameters specified above

Step 3) Start an Assessment for an indoor situation and select the area and the substance from the database, select Edition 2015 and choose as Type of Release: “Vapor Pressure”

Step 4) Set the temperatures to 20°C, and speed of gas release to 6 m3/hr (=100 ltr/min), pressure in casing to 101325 Pa and don’t use vapor pressure override Set the k-factor to 0,5.

Step 5) Don’t use the dilution override and set the efficiency of the ventilation to moderate (3) and set the availability to “Fair”

Step 6) Select a continuous release source and since the gas comes out of the release source and is a heavy gas, select “Heavy gas””

Step 7) Click next, followed by “Finish” and print the report

The result is this report:

Example 4 Leaking flange of a biogas system

(40 mbarg) in outdoor situation

Area parameters:

Length : 10 mtr

With: 5 mtr

Height: 3 mtr

Ventilation: Mechanical

Ventlation Capacity: 1500 m3/hr

Direction of ventilation: sidewards long

Ventilation measurements are not performed.

Step 1) Add a project, you can choose the name

Step 2) Add the area with the paremeters specified above

Step 3) Start an Assessment for an indoor situation and select the area and the substance from the database, select Edition 2015 and choose as Type of Release: “Liquid”

Step 4) Set the temperatures to 20°C, and speed of gas release to 6 m3/hr (=100 ltr/min), pressure in casing to 101325 Pa and don’t use vapor pressure override Set the k-factor to 0,5.

Step 5) Don’t use the dilution override and set the efficiency of the ventilation to moderate (3) and set the availability to “Fair”

Step 6) Select a continuous release source and since the gas comes out of the release source and is a heavy gas, select “Heavy gas””

Step 7) Click next, followed by “Finish” and print the report.

The result is this report:

Example 5 Leaking of a pump seal for xylene

(mixture) in an indoor situation

Step 1) Add a Project, you can choose the name

Step 2) Start an Assessment for an outdoor situation and select the substance (Xylene mixture) from the database, select Edition 2015 and choose as Type of Release: “Liquid”

Step 3) Set the temperatures to 20°C, atmospheric pressure to 1 bara and the pressure within the system to 3 barg. Select S = 0,25 mm2, set Cd to 0,99. Set percentage of direct evaporation to 10%. Set the k-factor to 1.

Step 4) Don’t use the dilution override and set the efficiency of the ventilation to moderate (3) and set the availability to “Fair”.

Step 5) Select a secondairy release source and select a Heavy gas, since the vapors are heavier than air.

Step 6) Click next, followed by “Finish” and print the report .

The result is this report:

This examination can be done by e.g. additional concentration measurements with a mobile PID or LEL detector. Be aware that these

This examination can be done by e.g. additional concentration measurements with a mobile PID or LEL detector. Be aware that these