Choose the right method for Hazardous Area Classification!

How important is it to use the right standards for ATEX hazardous area classification? In doing so, do you choose standards that provide the most favorable outcome, whatever that may be? Do you opt for specific industry standards? Are you obliged to use specific standards? In this article we try to provide answers to these questions, based on our years of practical experience.

Legal framework within EU

Each country has its own legal framwork for ensuring the health and safety of workers. Within the EU, this is, with regard to explosions safety specified in Directive 1999/92/EU. This international EU legislation is incorperated in the national legislation of member countries.

As an example: In the Netherlands, companies are obliged on the basis of the Working Conditions Act and the Working Conditions Decree. Specifically, article 3.5c of the Working Conditions Decree states:

"The hazards associated with explosive atmospheres and the special risks that may arise from them shall be assessed as a whole within the framework of the risk inventory and evaluation referred to in Article 5 of the Act before work commences and in the event of any significant change, extension or conversion of the workplace, the work equipment or the work process, and recorded in writing in an explosion protection document."

Subsequently, paragraph 2 of this article indicates that the assessment must include "an assessment of the likelihood of the occurrence and continuation of explosive atmospheres." In other words "the Atex zones must be established" because the Atex zones depend on this occurrence and persistence of explosive atmospheres.

Is the use of specific standards mandatory?

Nowhere states how the probability of the occurrence and persistence of explosive atmospheres should be assessed. Therefor this gives a direct answer to the question whether there is an obligation to assess Atex zones in accordance with a specific standard.

In practice, we have noticed that it is very important to make the right choice in the way Atex zones are established. There are a large number of norms, guidelines, standards and branch documents available that deal with Atex zones for specific or less specific installations. Some examples are:

EI 15 - Energy Institute 15, mostly for on- and offshore oil and gas applications

API 500/505 - mostly for onshore and offshore oil and gas applications.

EN 16985 - concerning spray cabins and powder coating cabins

EN 12779 - related to extraction systems for hot sawdust and chips

EN 60079-10 series, 2020 version for gas and dust explosion hazard

NPR 7910 series for gas and dust explosion hazard based on EN 60079-10-1, 2015 version

EN 13617 for fuel dispensers at filling stations

CECOD Guide for petrol stations (public)

BGR 104 Beispielsamlung (public)

etc.

In particular, the more general standards often give different results than the specific standards for specific installations. This can be both advantageous and disadvantageous. In general, the following applies: apply the standard that best fits the situation to be assessed, so specific standards or sector-specific guidelines provide a better foundation than the more general standards.

What are we actually assessing?

With assassing hazardous areas we assess how often an explosive atmosphere must be taken into account in a space or plant section. The following zone classes are distinguished:

Zone 0 for gas or Zone 20 for dust: Place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of dust, gas, vapor or mist is present continuously, for long periods or repeatedly (consider more than 10% of the time or more than 1000 hours);

zone 1 for gas or zone 21 for dust: place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of dust, gas, vapour or mist is likely to be present occasionally under normal operating conditions (consider less than 10% of the time / 1000 hours but more than 0.1% of the time /10 hours);

Zone 2 for gas or Zone 22 for dust: Place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation and, if it does occur, will persist for a short period (less than 0.1% of the time / 10 hours).

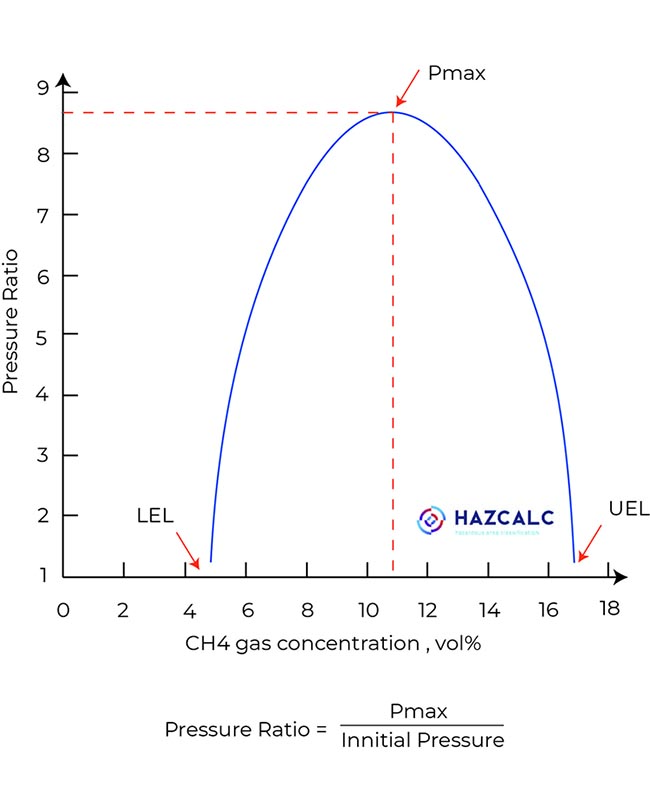

This means that the frequency with which the concentration of dust, gases, vapour or mist is above the lower explosion limit is assessed. After all, only when the concentration of fuel is above the lower explosion limit is a mixture explosive. This does not mean, by the way, that the combustible mixture is then highly explosive. It is only at an ideal ratio of fuel to air: this is the mixing ratio at which all fuel can burn with air, a stoichiometric mixture. Then usually the highest explosion pressure is obtained. This is illustrated in the following diagram.

This lower explosion limit (LEL value) of a substance, in terms of workplace atmosphere, is a particularly high limit. These are concentrations at which a person can no longer breathe or see comfortably. For dust explosion hazards the following rule of thumb is often used: "visibility less than 1 meter". These are often dust concentrations that are not readily present in workplaces. For gas explosion hazards, the following is illustrative:

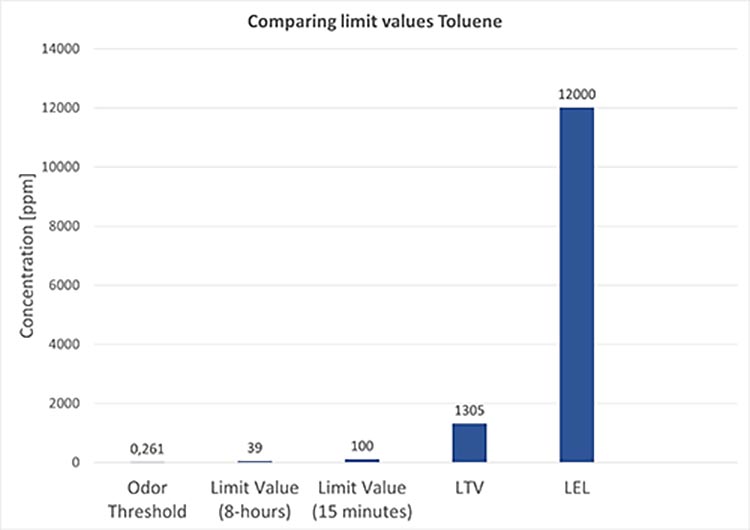

Take toluene, a flammable hydrocarbon with a flash point of 4°C and an LEL value of 1.2 vol% (12000 ppm). The figure below shows various limit values of toluene. This shows that our nose is a very sensitive measuring instrument: we can already smell toluene at very low concentrations. The LBW stands for Life-threatening Value: a concentration above which death or a life-threatening condition due to toxic effects may occur within a few days after a one-hour exposure!

The LEL value is almost 10 times the Life-Threatening Value (LTV)! So it is clear that a lower explosion limit is a very high concentration, which fortunately is often not easily reached in a workplace.

So why Atex zones in workplaces?

When defining Atex zones, unlike for example in exposure studies, one assumes that in case of a fault condition, fuel can be released from an installation into a room. The scenario used determines to a large extent whether explosive gas, vapour or dust clouds may be present in a room. Examples of this are: How large is a spill / liquid pool? What is the pressure in the pipework and what leakage area is taken into account? How does the room or source extraction ventilation system, relate to the accidental release of fuel? In addition to that, the methods usually also take into account a significant safety margin.

Simple methodology, large zones...

The above means that Atex zones must always be taken into account in working areas where flammable substances are handled. This is not to say that there will always be Atex zones; they must at least be properly assessed, even when non-hazardous atmosphere is the outcome. And as mentioned before, choosing the right standard / guideline or supporting document is very important. In general, the simpler the methodology, the larger the safety margins and the larger the Atex zones will be.

When applying simplified methods, the assessment is based on e.g. large leakage rates and this requires quite a lot of ventilation in order to obtain somewhat manageable zones. When we evaluate the same situation based on the European standard IEC 60079-10 series, the result, especially for gas explosion hazard, will be a much smaller zone. The method within the IEC 60079-10-1 standard is evaluated trough multiple CFD studies. When specific situations are assessed with specific advanced CFD models, the result will be an even more limited zone. Everything depends on the use of realistic and customised scenarios.

Hazcalc

For the assessment of Atex zones for flammable liquids or gases we developed Hazcalc. This is an online calculation model, which is based on scenarios, and fully compliant with the current European standard EN-IEC 60079-10-1. For more information visit hazcalconline.com/our-software or view the tool via a demo version app.hazcalc.com/register.